The manufacturing landscape in India is dynamically changing. Machinery that was once considered merely “functional” is now being upgraded to “high-performance” systems, which have altered the criteria for component selection dramatically. For several years, standard ball or cylindrical bearings were frequently chosen by many domestic OEMs due to their lower upfront costs. However, as the Indian industry spectrum that includes automotive, mining, and renewable energy, embraces global competition, the inherent technical limitations of these components are being revealed.

Nowadays, opting for Taper Roller Bearings India solutions doesn’t come down to a matter of choice, but it is actually technically necessary due to higher load densities, the requirement for exceptional durability under harsh weather, and the drive to reduce lifecycle costs. The insightful article below analyses the reasons behind this transition and gives a purchasing strategy.

1. The Geometry of Resistance: Handling Combined Loads

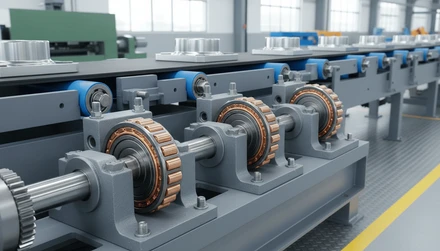

The main reason why tapered roller bearings became popular in contemporary equipment is that they can withstand combined loads—that is, the simultaneous radial and axial forces. In fact, in heavy-duty applications that constitute the majority of the Indian factory sector, instances of purely radial loads hardly exist.

Understanding Load Distribution

Ball bearings differ from tapered roller bearings in that they provide point contacts whereas the latter product line contact through the length of the roller. Tapered roller bearing geometry allows the bearing to distribute heavy loads over a larger surface area, thereby considerably reducing material stress.

- Radial Forces: These are basically the load of the rotating shaft and the attachments

- Axial (Thrust) Forces: This is the force that acts along the shaft and pushes it. One can find such forces in helical gears, steering mechanisms, and crushing equipment.

The apex of the tapered surfaces of the rollers and raceways meet at a common point on the bearing axis. This design ensures true rolling motion and creates a high capacity for thrust in one direction. I mean, look if a machine is running with some kind of angular misalignment or high-thrust intensity, then the standard bearing is going to fail prematurely. To me, it just feels like the industry has finally realized that the structural integrity of the entire drivetrain depends on this specific geometry.

2. Market Drivers: Why India is Pivoting Now

The bearing market in India is in the midst of a radical change. The “Make in India” campaign together with the landing of global OEMs have raised the bar for the local market.

High Load Density in Compact Designs

With a view to reducing the size and weight and at the same time boosting the power of equipment, there are no limits to the effort of designers. Whether it is a tractor for agricultural use or a gearbox for the industry, the device is required to carry a higher load without the size of the machine being increased. There is no other answer to this challenge than using tapered roller bearings, which can achieve the required load-carrying capacity whilst maintaining a small physical footprint.

Extreme Operational Environments

India’s industrial zones are often subject to harsh heat, humidity, and dust conditions. Normal bearings tend to heat up due to thermal expansion or run out of lubricant during such field operation. High-purity alloy steel tapered bearing shells are the ones best suited to maintain their dimensions even when the outside temperature is very high.’

The Rise of Infrastructure and Mining

Considerable capital is being put into Indian infrastructure such as roads, railways, and bridges. The construction of which demands the use of heavy-duty earthmoving machines. These machines have to withstand “shock load” situations, i.e., when the bearing must take a quick and very powerful impact. In fact, the tapered bearing design is so inherently strong that seasoned professionals in the trade consider it to be the best choice for them.

3. Critical Sourcing Decisions: A Technical Checklist

It is simply not enough to grab a catalog number when buying Taper Roller Bearings India. To achieve the desired level of performance, buyers should delve even further into what is behind the technical specs and country of origin of the suppliers.

A. Material Purity and Heat Treatment

The main factor determining the lifespan of a bearing is the steel quality. It is absolutely necessary to request vacuum degassed alloy steel of the highest grade when negotiating with an Indian market that sometimes receives “recycled” or lower-grade steel.

- Start with asking for proof of materials used. The rollers along with raceways need heat treatment like carburizing – this builds a durable outer shell. Inside stays softer, able to handle sudden loads safely. A tough center keeps cracks at bay even under pressure.

B. The Importance of Contact Angles

The outer ring raceway’s angle (contact angle) regulates the radial and axial loads’ capacity ratio.

- Metal/Plastic & Rubber Processes: Steep Angles are suitable for high-thrust applications such as steering hubs.

- Wire Drawing & Metal Working: Shallow Angles provide the best solution for high-speed applications with moderate thrust. Honestly, this is very common in Indian plants that have been recently commissioned. The thing is, it seems a simple matter, but if you choose the wrong contact angle it can cut the bearing life down by two-thirds.

C. Precision Ratings (ISO and ABEC)

Vibration tends to grow when machines push their speed limits, shaking parts harder than they should. A better-grade bearing – like P6 or even P5 – brings smoother spin while cutting down heat buildup along the way. Indian manufacturers aiming beyond local borders need to meet ISO rules; these aren’t just about fitting pieces together – they shape trust in how long things last.

4. Supply Chain Navigation

The Indian market is very diverse. Besides a handful of global giants like SKF, Timken, and Schaeffler dominating the scene, the bulk of the market is catered to by unorganized players.

The Risk of Spurious Products

Among the various challenges faced by an industrial plant in India, its downtime is the worst one and it is often caused by counterfeit or “spurious” bearings spreading in the market. These counterfeit bearings look exactly like the authentic brand, but inside, they are made of cheap steel and had no heat treatment performed.

- Plan: Always order from authorized industrial distributors. Check carefully for laser-etched codes on the bearing cone and cup. If the price is 30% lower than the average price, the risk of disastrous failure—and the resultant downtime—gives no room for initial savings to be justified.

Lead Times and Localization

The globalization of supply chain networks is being challenged by politics of time and geographical preferences. It is evident that more and more manufacturers are tending to produce locally thus it is only natural that through local production the lead times are minimized and the technical support team available just a call away during the time of commissioning they’d be in the same time zone.

5. Installation and Maintenance: The Actionable “Performance” Pillar

No matter how top-of-the-line the Taper Roller Bearings India are, if the human factor during installation is neglected, failure is almost certain. Special features of tapered bearings include manual adjustment during installation.

The “Preload” Equation

Bearings that roll with balls inside aren’t adjusted after fitting – most come set with space already built in. Tapered ones work only when matched in pairs, tension tightened right at setup.

- When there is too much preload, parts rub harder than needed. This extra pressure creates heat over time. The components wear out faster because of it. Friction builds up where it should not. Things start breaking down sooner than expected.

- It starts shaky when there’s not enough tension – rattling kicks in, sounds get rough, parts shift out of place. People keeping things running should learn how to check alignment with gauges or adjust tightness using measured turns instead of guesses. Machines cost serious money, yet we still leave the last steps to chance, trusting touch or instinct. This habit needs to stop.

Lubrication Strategy

Grease plays a very important role in the Indian environment. This season’s temperature trend shows that the base oil in grease can bleed out faster due to high ambient temperature.

- Plan: Synthetic-based lubricants with high-temperature additives to be used in heavy-duty industrial gearboxes. Moreover, a strict re-lubrication schedule to be adhered to since dust infiltration in Indian factories is far higher than in Europe or North America.

6. The Future: Industry 4.0 and Smart Sourcing

In the next two years or so, the performance expectations of Indian machines will be raised to a level where ‘zero downtime’ will be the goal – achieved by incorporating sensor technology right into the bearing housing.

Predictive Maintenance

Today, smart Taper Roller Bearings India can be found in some of the highest-value assets such as wind turbines and railway bogies. These bearings really pay attention to:

- Vibration patterns: Smallish surface fatigue can be detected before failure by very precise testing.

- Temperature spikes: Real-time indication of lubrication failure.

- Acoustic Signals: Misalignment problems visually identified.

From the perspective of a B2B management leader, embracing smart bearings heralds the era of ‘repaired after the fact’ to that of ‘managed before the fact.’ Basically, it is a long-term plan to increase the plant’s capability with one major injection of funds.

Conclusion

Replacing standard ball or roller bearings with tapered roller bearings in Indian equipment can be viewed as an industrial maturity sign. The nation is slowly leaving the era of “cheap and frequent replacement” behind and entering the era of “high precision and reliability over a long period.”

Think about these points before getting Taper Roller Bearings India for your next job. Machines rely heavily on how well the bearing works beneath them. Losing just a single day of operation often adds up to more than what you’d spend on bearings over twelve months.

The most important points to remember are:

- Pay Attention to the Geometry: Choose tapered rollers every time there is a dual radial and axial load.

- Material Verification: Demand carburized alloy steel with complete traceability to withstand the harsh Indian conditions.

- Preload Control: Avoid the “too tight/too loose” dilemma by standardizing installation procedures.

- Strategic Sourcing: Stay away from the unorganized market since the problem of counterfeit products in India is too serious to be ignored.

Indian manufacturers will be able to take their machinery to not only fulfill the demands of the domestic market but also to compete internationally by concentrating on these technical and strategic pillars. Time to market and quality are no longer mutually exclusive. Two faces of the same coin are what they become with the right components.